- Construction materials : AISI316 / AISI304 / Cast Iron GG25

- Available Stators: NBR, EPDM, HYPALON, FKM

- Flow up to 75 m3/h

- Max pressure up to 12 Βar

- Max temperature: Up to 100°C

- Max viscosity: 500.000 cSt

- Two different kind of seal is available: PTFE Gland packing and mechanical seal Cer/graph/FKM or Viton , Tungsten/tungsten/EPDM or FKM

ATLAS – Progressive cavity pump

Features

- Length Geometry

- Length Pitch

- Lower Sliding Velocity

- Higher Performance compared to classic geometry

- Minor service requirements

- Stability in pressure & flow due to longer sealing lines

- Improved flow characteristics

- Reduced Vibration, Turbulence, shear rates & pulsation

- Smooth and performance

- Improved volumetric, Mechanical & overall efficiency

- Block construction minimizes overall dimensions, providing a shorter pump length. Eliminates the need for coupling and cover protection.

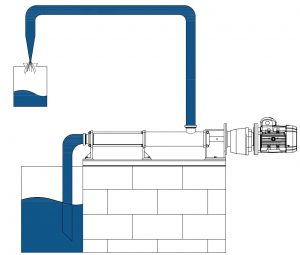

- Can be installed vertically or horizontally to suit the application. Can run in either direction.

1. Mechanical seal

2. Connnection rod

3. Discharge hhousin DIN 11851

4. Stator

5. Rotor

6. Suction Housing DIN 11851

Basic Pump Carateristic

Reversible operation

The pump can work in both the 2 directions of operation with interchange of the flow of the liquid inside the network without a problem as many times as we want with a simple interchange of the motor direction.

Self Priming

Self priming of the product up to 4m from a dry starting point within a few seconds.

Smooth and steady pumping of the product without pressure from the spikes (even flow rate is ideal for filling, dosing or filtration).

Suitable for the transfer of delicate and viscous liquids

Up to 500.000 cps, also for paste and cream liquids, even with solid suspension, without any wear out or damage.

Vertical Operation